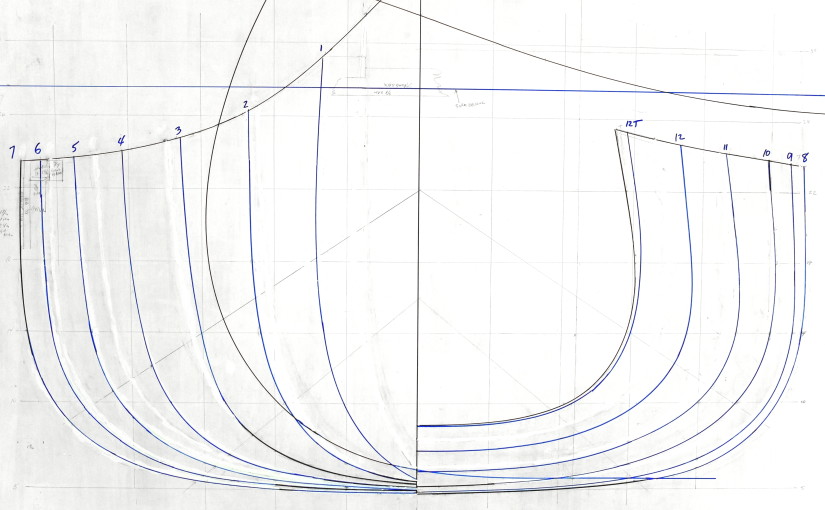

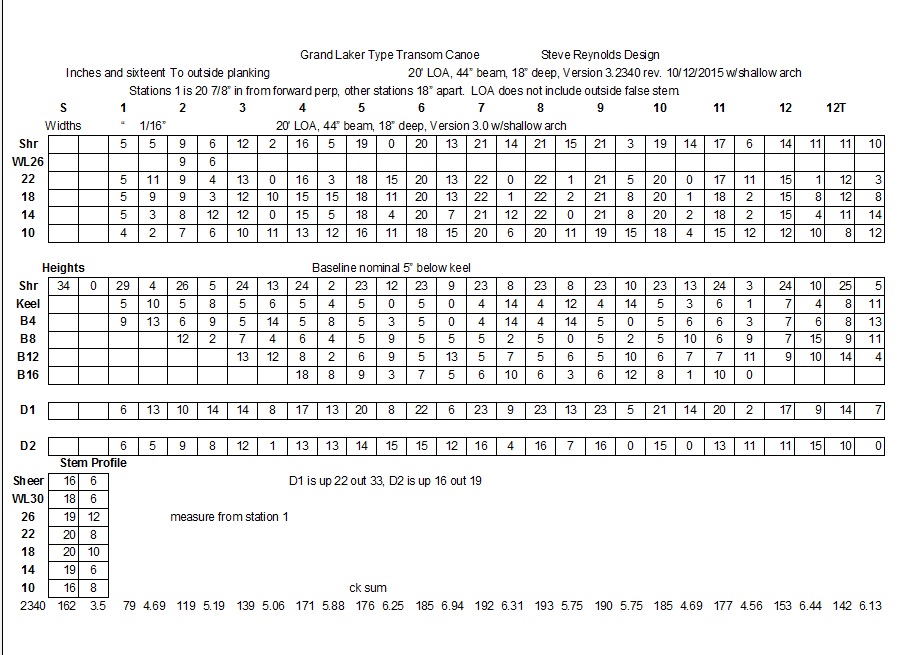

I have now drawn these lines 4 times – starting at 1/8 scale, to the dimensions of the boats I saw in western Maine, which were narrower and more shallow than the Dale Tobey boats, and then three times at 1/2 scale. The lines above have stations spaced 18″ apart which is adequate for constructing a solid form, and the forward station is placed approximately 20″ in from the outside of the stem. The station at the stern is just inside the transom. I drew the body plan at full size (above) and lofted the waterlines, buttocks and diagonals at half scale to fair the body. This method I think was satisfactory but I will know for sure when I assemble the mold stations and check the fairness of the lines. The lofting is time consuming. It took me the best part of 3 days to develop the 18″ station plan from the 24″ station plan. Lofting a 20′ boat at full size requires a space at least 24′ long, plus cost of the plywood for the surface, and I hope the 1/2 scale method was good enough. See Howard Chapelle’s Boatbuilding for a thorough discussion of lofting. Here is the table of offsets for this version :

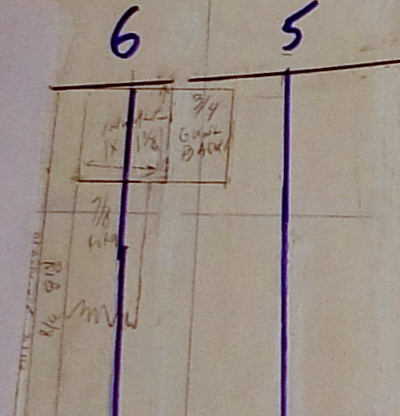

Picking up the shapes of the form molds from the body plan – The body plan is drawn to the outside of the planking and the lines must reduced to get the shape of the plywood stations which make up the form. The total thickness of the reduction is: 3/16″ planking plus 3/8″ ribs plus 7/8″ form sheathing, or 1 7/16″. There is also a cutout in the form molds for a backer behind the inner gunwale, which will be 3/4″ x 1 1/8″. The form sheathing is clear pine strips 7/8″ x 1 1/8″ – I could probably have used 3/4″ but will try the 7/8″ for a more solid form, although it will make fixing some of the strips more difficult to twist into position.

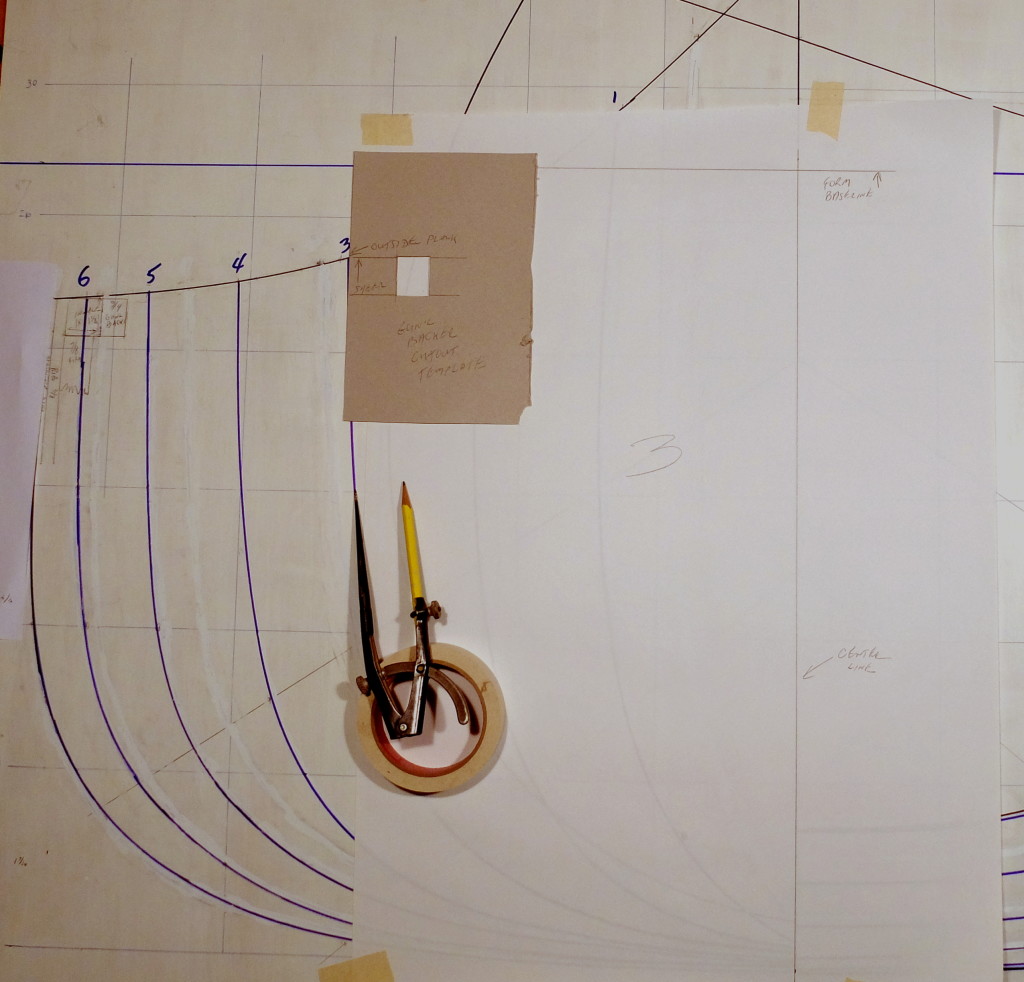

Picking up the shapes of the form molds from the body plan – The body plan is drawn to the outside of the planking and the lines must reduced to get the shape of the plywood stations which make up the form. The total thickness of the reduction is: 3/16″ planking plus 3/8″ ribs plus 7/8″ form sheathing, or 1 7/16″. There is also a cutout in the form molds for a backer behind the inner gunwale, which will be 3/4″ x 1 1/8″. The form sheathing is clear pine strips 7/8″ x 1 1/8″ – I could probably have used 3/4″ but will try the 7/8″ for a more solid form, although it will make fixing some of the strips more difficult to twist into position. I set the dividers at 1 7/16″, hold them at a right angle to the curve of the body plan, and trace a line onto a piece of paper placed over the body plan. I can see the lines of the body plan through the paper. I draw in the cutout for the gunwale backer. I don’t trust the paper to retain is shape for days, so I transfer the new line right away to my mold material – 3/4″ CDX plywood.

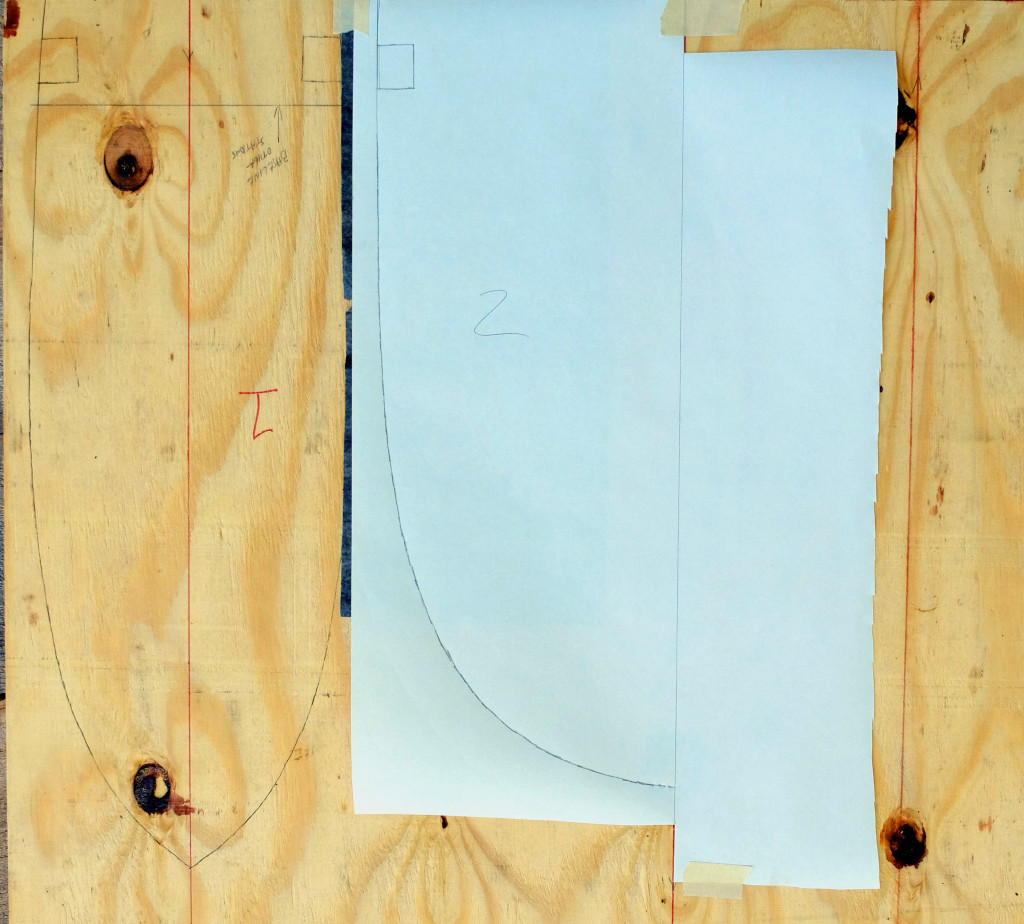

I set the dividers at 1 7/16″, hold them at a right angle to the curve of the body plan, and trace a line onto a piece of paper placed over the body plan. I can see the lines of the body plan through the paper. I draw in the cutout for the gunwale backer. I don’t trust the paper to retain is shape for days, so I transfer the new line right away to my mold material – 3/4″ CDX plywood.

The mold shapes transferred to plywood using carbon paper – keep everything square. Now I can start assembling the form.